Making the Most of Modular Construction

A Win-Win for Airport Projects

Many airports are facing the dual challenges of aging infrastructure and increased passenger demands. A 2025 report from Airports Council International (ACI) estimates that European airports will need to invest €360 billion in improvements by 2040, largely driven by the need to modernize, enhance operational resilience, and expand capacity.

Deploying a modular construction approach offers a way to make these necessary upgrades to facilities with minimal disruption, reduced timelines and without demolishing them entirely.

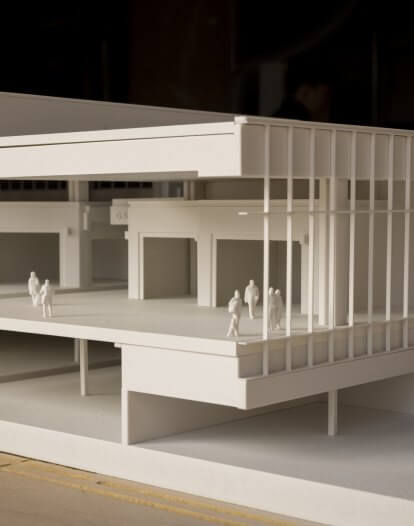

Modular construction is not new within the building industry and has several associated typologies, such as modern methods of construction (MMC), design for manufacture and assembly (DfMA), and kit of parts. However, a handful of aviation projects have now benefitted from using large-format volumetric modules, which are constructed off-site in ‘mod yards’ and moved as substantially complete units into their final locations.

More airports are considering this approach where construction activity across an already busy facility is a significant challenge. Two recent U.S. examples are the High C Gates at Dallas-Fort Worth International Airport (DFW) and the Corgan-designed Concourse D widening project at Hartsfield–Jackson Atlanta International Airport (ATL). These projects illustrate the benefits that this type of off-site modular approach can have on project timeline and costs.

Reduced Downtime = Operational Savings

Regardless of the reason for a gate closure — be it weather, security, or construction — the cost of closing a gate is high. Corgan’s estimates show that airlines and airports lose between USD$300,000 and USD$400,000 in revenue each day a single gate is closed. Therefore, when planning upgrades, the cost of shutting down gates for construction can be prohibitive.

Off-site modular construction, along with careful phasing, can significantly reduce the financial and operational impact of upgrades on both the airport and airline. In modular construction, the major built components — ‘modules’ — can be constructed away from the operational airfield (often completely landside) and moved into place when they are in a near-complete stage, keeping more gates operational through an enhanced project timeline. Modules are transported and installed on the existing concourse at night to minimize disruption to passengers and airport operations. Once positioned, they are seamlessly joined to enclose the structure and integrate building systems, enabling interior work to proceed. This approach further reduces operational impacts while boosting construction efficiency.

This method was used to rapidly replace American Airlines’ High C Gates at DFW while flights were on a reduced schedule during the pandemic. After the original five gates were demolished, the DFW-led design-build team installed the modular envelope while the Corgan team, led by American Airlines, designed the interior fit-out of the spaces. Coordination between the two design and construction teams facilitated early access for interior work prior to construction being completed on the shell and core, further increasing efficiency in both cost and schedule. This overlap in construction work areas, combined with the offsite construction of the modules, saved the airport four months compared to a traditional construction approach. As a result, all gates were fully operational again when flight schedules returned to normal.

By using modular construction for the current Concourse D widening project at ATL, airlines are saving an estimated USD$500 million in otherwise-lost revenue. Minimizing disruptions to daily operations, the complex renovations are being conducted in a multi-phased approach, enabling the airport to remain operational, significantly reducing both gate closure time and the overall project timeline.

Gate closure time is reduced by combining modular and traditional methods: the modular expansions allow for new gates or walkways to be opened, which in turn facilitates traditional construction at the gates on the opposing side over the existing concourse. In this case, the modular construction schedule saves ATL more than 40 weeks of gate closures and reduces gate downtime by 20% compared to a traditional construction approach. To increase the speed of the overall construction timeline, the team closed eight gates at once, rather than doing a few at a time. This saved nearly three years of phased construction, taking the project from a 9-year timeline to a 6-year timeline. In phase two, the team proposes to close 10 gates simultaneously, saving an additional five months.

More Efficient Construction

Modular construction delivers substantial safety, efficiency, and logistical advantages over traditional airside methods. By relocating much of the work to the off-site mod yard, crews spend significantly less time airside, reducing exposure to aircraft, traffic, foreign object debris, and associated risks to both workers and airport operations. Key scope packages such as superstructure, envelope, vertical transportation and MEP can complete much of their work in the yard, minimizing airside activity.

From a logistics standpoint, the mod yard provides more staging space and eliminates restrictions on hot works and welding common to airside environments. Materials, equipment, and rentals can be delivered without the constraints of airport security, and the controlled environment supports the high precision needed for seamless module-to-module connections. The yard is also less impacted by adverse weather, as its activities are typically off the critical path and unaffected by airport weather delays.

Modular construction also enables resource levelling. In traditional projects, manpower demand fluctuates sharply between phases; with a mod yard, different phases can progress simultaneously. When airside work slows, resources can be shifted to yard activities, improving overall productivity.

Positioning the mod yard beyond the restricted zone of the airport further streamlines scheduling. Work is no longer limited to badged personnel, onboarding can begin immediately while the three-week badging process runs in parallel, and workers save roughly one hour per day otherwise lost to security screening — equivalent to 10% of a 10-hour shift. On a recent UK project, involving the construction of a new pier, the main contractor reported a 200% increase in labour efficiency with modular methods, alongside fewer site incidents and reduced operational impacts.

Sustainability Benefits

As part of Corgan’s ongoing research into this scale of modular construction, we are assessing improvements for sustainability and carbon reduction. Adopting modular construction can mitigate some negative environmental impacts associated with standard design and construction practices, if considered early. Large modular construction can facilitate more efficient material use as well as the incorporation of recertified structural components, due to their repeatable nature. The accelerated design schedule associated with a modular design enables more accurate reporting of carbon emissions at an earlier point in the design process. In turn, this allows earlier evaluation of potential carbon saving measures and integration into the design without impacting the cost or schedule. The use of a mod yard provides more control over negative environmental impacts such as waste generation and airborne contaminates.

Implications for the global aviation construction industry

As we gain more experience in using modular construction at airports, we are learning how to maximize the benefits and navigate the limitations of this construction type. For large, complex airport projects, the chief benefit of large modular construction is in minimizing the duration of gate closures — existing gates remain operational longer and new gates are opened sooner. Modularization and componentization can also be used on a smaller scale to make smaller renovations or upgrades more efficient. For example, modular restrooms, communications rooms, and other building elements can be “unplugged,” replaced, and reinstalled with prefabricated pieces, saving downtime for parts of the facility that affect operations and passenger experience. That said, the possibilities around greater module size and higher state of module completion (e.g. modules including glazing, lifts and escalators, ceiling and floor finishes) are evolving. As more airports upgrade their aging facilities, modular construction is poised to become an increasingly important tool in aviation infrastructure development, delivering a win-win for construction and operation.