From Strategy to Performance: Net-Positive Design

The formula for a net-positive design is simple: the energy generated needs to be greater than the energy used. Reaching those goals, however, requires exacting attention to detail, from the materials used to the occupancy schedule. Varun Kohli details how Corgan’s sustainability team, Echo, delivered a net-positive design for Wells Fargo’s new campus in Irving, Texas.

What does it take to make a net-positive corporate campus?

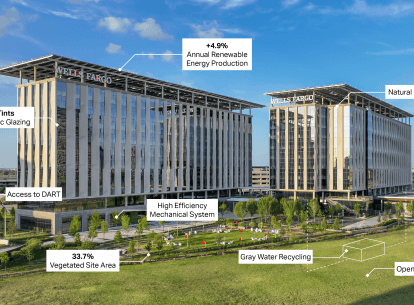

Wells Fargo’s new campus in the Las Colinas development of Irving, Texas, isn’t just pursuing LEED™ Platinum certification: it will be net-positive, meaning it will generate more energy than it uses. This feat — a first for both Wells Fargo and Corgan — is possible through extensive product research, site analysis, and carefully designed interventions.

The campus includes two 10-story office buildings and one six-story parking garage, with space on the site’s eastern tract to expand as needed. To achieve a net-positive campus, the sustainability team carefully analyzed the materials used, optimized the building operations, and maximized on-campus renewable energy generation.

The process began with a site analysis

After analysis, it was determined that the site’s energy use intensity (EUI) is 38.1, which is around 28% lower than the average for financial services offices. The EUI is based on the site’s physical features and climate as well as the design and operations of the building. The site itself got the project off to a good start, as did its accessibility via mass transit. The proximity of the site to Lake Carolyn isn’t purely scenic – the lake also provides non-potable water for irrigation of the campus’s green spaces. In combination with a selection of low-water use plants, water use is 58% less than a baseline project.

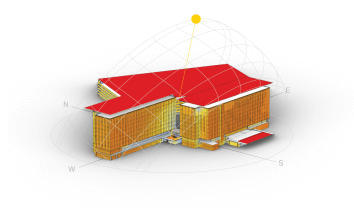

The solar radiation analysis informed several key design decisions.

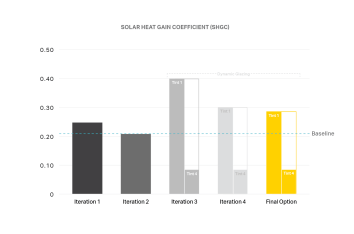

A solar radiation analysis of the site using EnergyPlus and DesignBuilder software showed the building energy cost estimates for a one year period. Predictably, the southern façades have higher rates of energy use, calculated as kilo-British Thermal Units per square foot (kBTU/sf), which represents the energy needed to heat or cool a specific area over a year. These insights informed key design decisions, including strategic window placement to optimize solar heat gain and selection of a more efficient cooling system to address the increased cooling load. Open office areas and a long, narrow floorplate means that daylight is available throughout the office space. The campus also includes green space occupying more than a third of the site, which offsets the heat island effect, promotes biodiversity and recreation, and improves stormwater management.

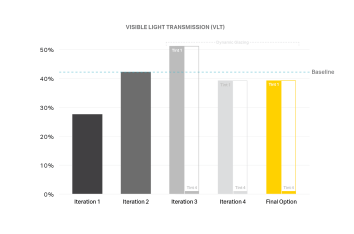

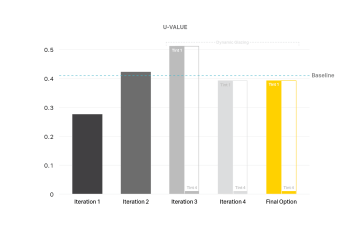

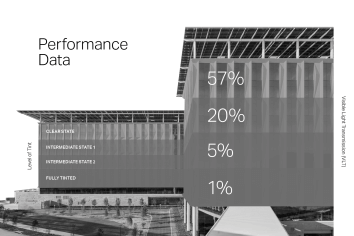

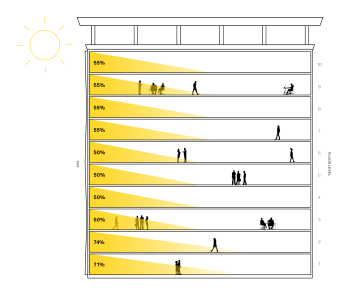

The selected glazing, from SageGlass, has four tint levels with a SHGC ranging from 0.41 to 0.08 and VLT ranging from 57% to 1%. The glazing automatically adjusts to the level of sunlight to allow more light in when the sun is lower and blocking more heat gain when the sun is high. The glazing has a U-value of 0.28, which is achieved via a double pane system and provides better insulation from outside temperatures.

The selected glazing has four tint settings that range from 57% to 1% VLT.

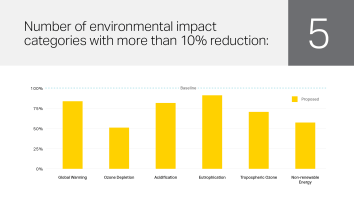

The One Click LCA assessment represents the total life cycle impact over a 60-year service life.

The team also analyzed concrete options with embodied carbon in mind.

As the other major material used for the building envelope, the selection of concrete was also important to the campus’ sustainability. The whole building life cycle assessment — which includes not just the material itself but also its transportation, maintenance and replacement, and deconstruction over an estimated building service life of 60 years — indicated that concrete was an embodied carbon hotspot.

Using One Click LCA, the team analyzed the embodied carbon of baseline construction materials compared to Portland limestone (Type IL) cement. Type IL cement incorporates more limestone in its mixture than the typical Type I/II cement, which reduces the amount of CO2 produced in its manufacture without altering its performance. By using Type IL cement for the cast-in-place portions of the office buildings and in the pre-cast concrete for the garage, the team reduced the greenhouse gases by 14% when compared to a baseline project.

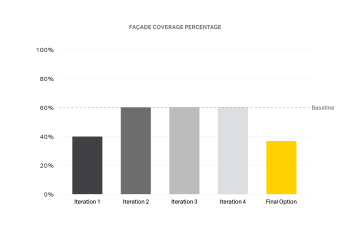

Balancing the ratio of glazing to concrete was the final step for envelope design

To obtain an optimum balance of high natural daylighting and low heat gain, the team tested various levels of glazing. Ultimately, approximately 60% of the envelope of both buildings is transparent glazing, with the rest being precast concrete.

The solar radiation analysis informed what percent of each building face is glazing.

With slightly more glass than concrete, this balance — along with the building orientation — facilitates a high level of daylight and sunlight exposure. For both buildings, floors one and two achieved more than 70% Spatial Daylight Autonomy (sDA), meaning over 70% of the floor space of these two buildings gets enough natural light for a significant portion of the year. The remaining floors achieved more than 50% sDA. By relying more on natural light, Wells Fargo saves electricity on artificial lighting. Correspondingly, the Annual Sunlight Exposure (ASE) was 20% for the first floor, this means 20% of the floor area receives direct sunlight exceeding 1000 lux for more than 250 hours per year. The remaining floors have an ASE of less than 10%, minimizing excessive heat gain through the building envelope during summer months.

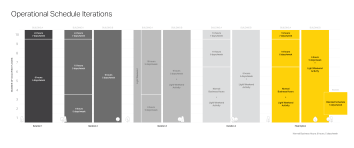

Optimizing the operation schedule and occupation density

Various scheduling options were investigated to find an option that is both efficient operationally and practical for the tenant. To start, the team tested what the operations would look like with just building A fully occupied, with one floor occupied 24/7. In an iterative process, they evaluated other schedules, first incorporating building B and then adding kitchen operations. Of all variables, the operating schedule has the largest impact on energy use; by working with the client, Corgan was able to eliminate 24/7 energy use and just one floor is occupied each day of the week.

The team reviewed four schedule iterations before landing on the final schedule.

Finding optimal balance between performance and energy use.

Designing a net-positive campus also requires precision in developing the buildings’ lighting loads, plug loads, and mechanical loads. The team reviewed the operating load for each of the occupancy schedule to balance performance with energy use.

The campus's lighting and plug loads were calculated for each schedule and occupant density that the team developed, considering equipment type. The calculated energy use helped to determine which schedule offered the best balance of operations and efficiency. The result for the lighting loads is 0.45 watts per square foot (w/sf) in the office buildings and 0.024 w/sf in the parking garage, while the plug load is 1.44 w/sf in the occupied floors. The site is to be lit on an equivalent power output of six hours per day due to the daylight and occupancy settings, significantly less than the 8 to 10 hours that is common in office buildings. The result is 42% electricity savings compared to the building baseline.

For the mechanical loads, the team reviewed five options, including geothermal using the lake and vertical well fields, air-cooled chillers to eliminate water use in the water-cooled system, and underfloor air distribution from a chilled water plant. To achieve the best balance of efficiency, performance, and cost, the team used both water-cooled chillers with a water-side economizer between chilled water and condenser water loops and parallel fan-powered boxes with electric heat. The leaving air temperature was set to 50 degrees, resulting in lower airflow and fan energy use. The chiller efficiency is 0.565 kilowatts per ton (kw/ton) at a full load and 0.3498 kw/ton at non-standard part load value (NPLV). Compared to the baseline chiller efficiency of 0.539 at NPLV, the selected system is around 35% more efficient.

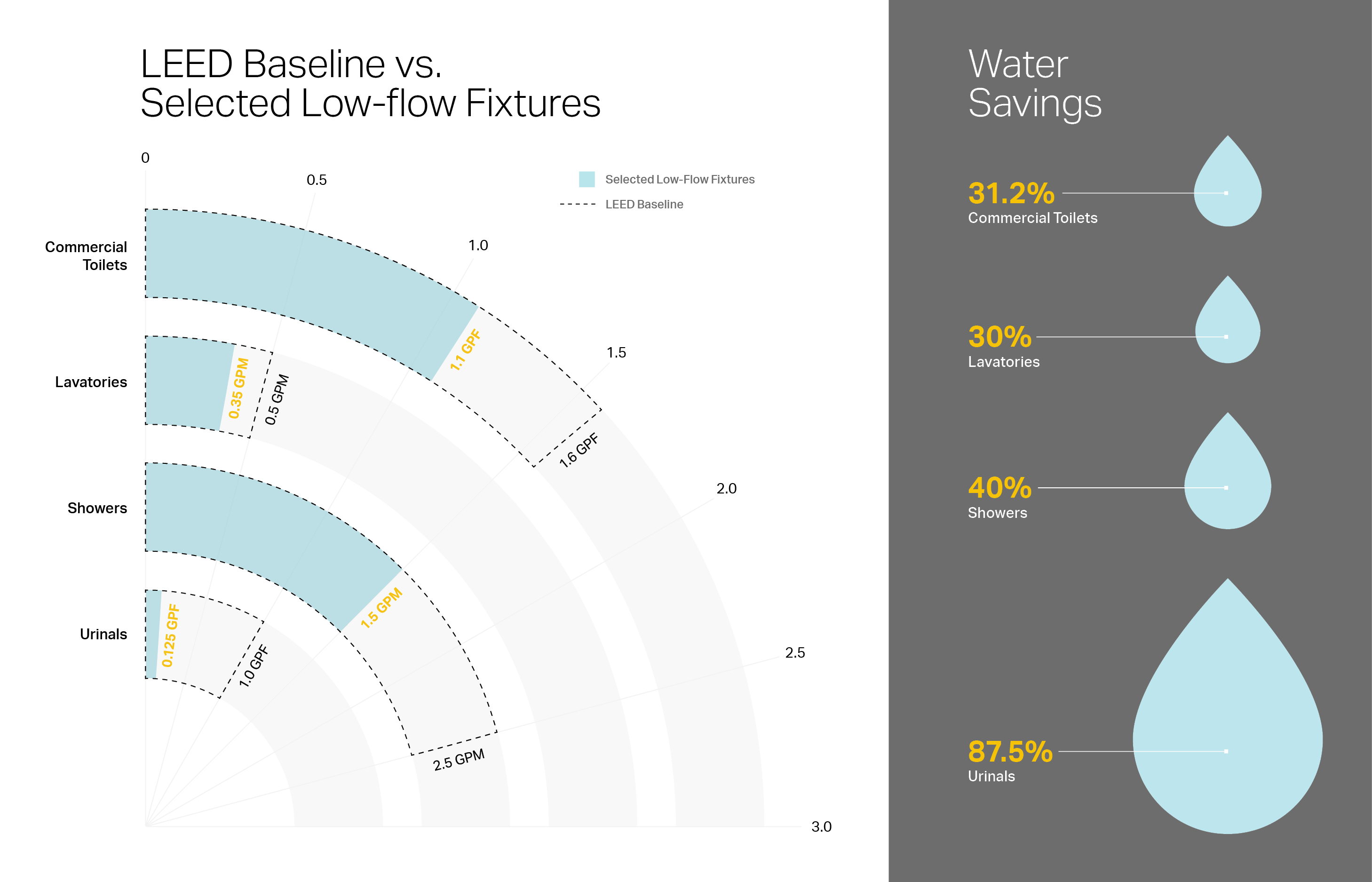

Measures were taken to reduce indoor water usage as well. Low-flow fixtures were selected for the bathrooms and showers, significantly reducing water use compared to the LEED baselines for gallons per flush (GPF) and gallons per minute (GPM). These measures resulted in 45% reduction in indoor water use compared to the baseline. To reduce water use further, the team decided to collect graywater (both condensate and from flow fixtures) to use in flush fixtures and the cooling tower, resulting in 74% in total water savings.

Maximizing on-site energy generation

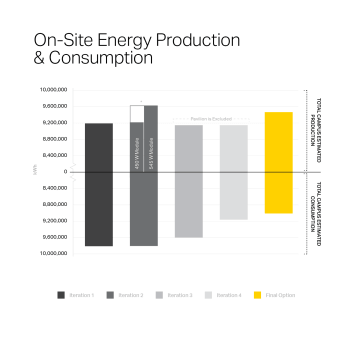

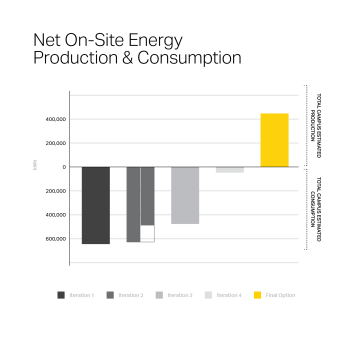

The final piece of the net-positive puzzle is maximizing on-site energy generation. Due to the campus’s sunny Texas location, solar panels were the best option. Based on the materials selected, scheduling, and mechanical load minimization, the Wells Fargo campus is projected to consume 9,008,908 kWh of energy per year.

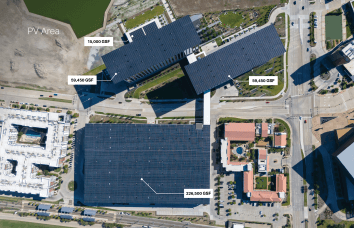

To generate this approximately 9 million kWH of energy, the design maximizes photovoltaic (PV) arrays on rooftops across the complex. Over 360,000 square feet of solar panels will be installed, with 62% located on the parking structure. The remaining panels will be distributed across the office buildings (Buildings A and B) and the dining pavilion, accounting for 16.5% and 4% respectively. Dallas has abundant sunshine, with an average of 232 sunny days per year, making it a prime location for solar power generation. Leveraging this advantage, the campus is projected to produce 9,458,000 kWh of energy each year, bringing the project’s net positive energy (NPE) to 4.9%. The extra electricity can be returned to the grid or, in the future, saved to site batteries if Wells Fargo chooses to install them. The team also calculated that if the parking garage’s solar canopy is extended, the NPE could reach 8.6%.

By elevating the PV arrays 10 to 20 feet above the top deck of the parking garage and office buildings, the design team was able to create an uniterrupted surface, maximizing each square foot available.

Designing for now and later

Designing a net-positive corporate campus is an ambitious goal, and one that is not feasible for every project. It takes a committed client, a dedicated team, right site and set of circumstances, and exacting attention to detail to make happen. However, when successfully executed, the results can be transformative — not only for the environment but also for the employees and surrounding community. As a model for future developments, the Wells Fargo campus proves that with the right vision and resources, it is possible to create spaces that not only meet our needs today but also pave the way for a more sustainable and resilient future.