EPScrete: Rethinking Styrofoam Waste as a Potential Green Building Material

Reframing Waste as a Material Opportunity

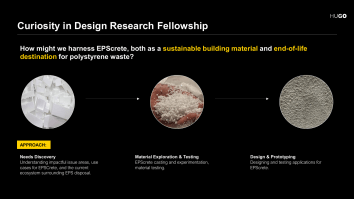

Amid growing urgency around climate change and the environmental cost of construction, the search for alternative building materials has accelerated. Expanded polystyrene (commonly known as EPS or Styrofoam), is a lightweight plastic that rarely enters effective recycling streams, illustrates the dilemma: abundant, persistent, and largely destined for landfills. EPScrete — a lightweight concrete that incorporates EPS beads — offers a way to rethink this overlooked waste stream. This research project explores how EPScrete might contribute to ongoing industry-wide conversations around circularity, resource efficiency, and material innovation in the built environment.

From Concept to Experimentation

The project set out to understand EPScrete not simply as a technical mixture, but as a material opportunity. What forms might it take? What inherent material properties might be leveraged?

Exploring EPScrete required a holistic approach to both the material and its context. The project included:

• A thorough literature review to understand the current landscape surrounding EPScrete and under-investigated areas for research.

• Understanding EPS waste systems to identify why this material remains underutilized but full of potential.

• Developing a method for processing EPS into usable bead form while preserving the air pockets critical to EPScrete’s performance.

• Casting and testing early material samples to gain insight into how EPScrete performs across various metrics of compressive strength, impact resistance, and acoustic performance.

• Creating prototype components — including acoustic tiles, interlocking bricks, and breeze blocks — that illustrate how EPScrete could be expressed at architectural scales. These prototypes were not intended as finished products, but as small, tangible explorations to promote larger conversations around EPScrete’s design potential.

Key Findings

EPScrete is lighter than traditional concrete and may play a promising role in reducing the weight of non-structural components.

Due to its reduced mass compared to traditional concrete, EPScrete is better at dissipating sound than blocking it, making it advantageous for finishing/surface applications rather than structural components.

EPScrete’s lower impact strength suggests it should be treated more like an acoustic or insulating composite rather than a structural concrete—ideal for lightweight, interior, or hybrid assemblies where its thermal and sound properties can be fully utilized.

A 37% EPS mixture provides the best performance balance. Among all formulations, the 37% EPS mix consistently showed the strongest compressive performance, highest impact resistance, and the most favorable overall behavior—even though it still falls below conventional structural standards. This blend offers the most promising baseline ratio for future refinement and architectural use where lightweight qualities are prioritized.

Explore the Full Report

The complete EPScrete report expands on these insights, detailing the research process, testing methodology, prototyping explorations, and broader implications for sustainable material futures. Read the full report to see how rethinking a single waste stream can spark new directions for low-impact, circular design.

For further questions or inquiries related to EPScrete, please contact amy.qu [at] corgan.com (amy[dot]qu[at]corgan[dot]com).