Prefab Takes Flight at U.S. Airports

Current projects at Los Angeles International Airport (LAX) and Hartsfield-Jackson Atlanta International Airport (ATL), while not the first in the country to use remote construction, nevertheless illustrate the potential of different variations on the approach. In Atlanta, architects Corgan and Goode Van Slyke are relying on a hybrid of modular and traditional construction to expand ATL’s 44-year-old Concourse D by 75 percent to accommodate larger airplanes and more travelers.

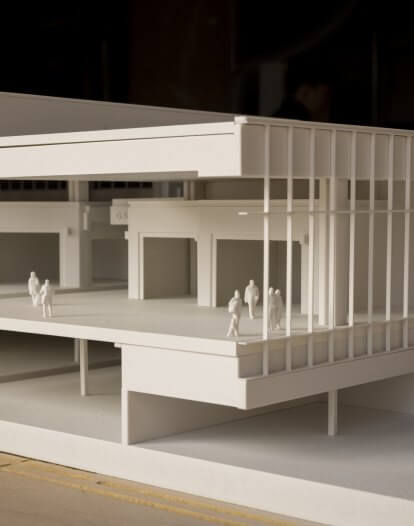

The team behind the expansion of Concourse D at ATL—the world’s busiest airport, with more than 100 million travelers in 2023 alone—is taking a slightly different tack, combining prefabrication with stick-built construction. The $1.4 billion project will widen the structure from 65 feet to 99 feet and extend its overall length by 288 feet. Ross Payton, aviation-sector leader at Corgan, says the revamped concourse will be more comfortable for travelers. It will have a taller interior volume, with 18-foot ceilings; larger hold rooms, with 20 percent more seating; roomier circulation spaces; more food options; and larger restrooms. When both north and south wings are complete, Concourse D will have 34 gates for next-generation aircraft.

The expansion is being implemented in phases, so that no more than eight gates are taken out of operation at any one time, a mandate from the client, explains Todd McClendon, senior vice president of aviation with WSP, the project’s program manager as part of a joint venture with H.J. Russell and Turner & Townsend. Starting with the north wing, contractors are building steel-framed, shoebox-like modules—some as large as 30 by 192 feet—in a nearby assembly yard and, as with the LAX project, moving them into place overnight with Mammoet’s SPMTs. The team will next rely on more conventional techniques to build over the existing two-story concourse, and, once the new enclosure is complete, demolish the original upper level from within.

As of September, the first five modules had been put in place, with six new gates already in use. The north wing is expected to be complete by the summer of 2027, and the entire concourse two years later. According to WSP’s initial estimates, the combination of off- and on-site construction will shave eight to 10 months off the project timeline compared to a more conventional approach. It will also keep a maximum number of gates in operation at any one time. “In terms of per-day gate revenue, it made total sense,” says McClendon.

Prefabrication or modular construction won’t be a good fit for every airport. But if the projects in Atlanta and Los Angeles deliver on their promises, we will be seeing many more relying on these strategies.